Deba present at Job Fair of Tuesday 22th March in Ghent

/in Nieuws-Deba, Nieuws-HetVeer /byTomorrow, Tuesday 22th March, Deba will be present at the Job Fair in Ghent. This event takes place at the International Convention Center (ICC), which is settled in the Citadel Parc. Come over, visit our stand from 12 am till 06 pm, and find the job of your dreams with us. You may already take a look on the website of our holding “Het Veer”, where you find all our open vacancies.

Practical information

Place? The ICC (International Convention Center), Ghent.

Address? Citadel Parc. Van Rysselberghedreef 2, post box 1 – Citadel Parc, 9000 Ghent.

Date? Tuesday 22th March 2016, 12 am-06 pm.

More information? Check out the website of the organization.

Deba present at Job Fair of Tuesday 22th March in Ghent

/in Nieuws-Deba, Nieuws-HetVeer /byTomorrow, Tuesday 22th March, Deba will be present at the Job Fair in Ghent. This event takes place at the International Convention Center (ICC), which is settled in the Citadel Parc. Come over, visit our stand from 12 am till 06 pm, and find the job of your dreams with us. You may already take a look on the website of our holding “Het Veer”, where you find all our open vacancies.

Practical information

Place? The ICC (International Convention Center), Ghent.

Address? Citadel Parc. Van Rysselberghedreef 2, post box 1 – Citadel Parc, 9000 Ghent.

Date? Tuesday 22th March 2016, 12 am-06 pm.

More information? Check out the website of the organization.

SGC again present at the Hannover Messe

/in Nieuws-HetVeer, Nieuws-SGC /byAs in the previous years, SGC-SwitchGear Company will again be present at the Hannover Messe. This international fair of industrial technology will take place from Monday 25 to Friday April 29th. You will find SGC at booth B64 in hall 13.

This five days event takes place in the city of Hannover in northern Germany. Come and visit us, put your questions and discover the latest innovations that SGC has in store! More information can be found on the website of the Hannover Messe organization.

SGC again present at the Hannover Messe

/in Nieuws-HetVeer, Nieuws-SGC /byAs in the previous years, SGC-SwitchGear Company will again be present at the Hannover Messe. This international fair of industrial technology will take place from Monday 25 to Friday April 29th. You will find SGC at booth B64 in hall 13.

This five days event takes place in the city of Hannover in northern Germany. Come and visit us, put your questions and discover the latest innovations that SGC has in store! More information can be found on the website of the Hannover Messe organization.

Mevoco again present at the Hannover Messe

/in Nieuws-HetVeer, Nieuws-Mevoco /byAs in the previous years, Mevoco will again be present at the Hannover Messe. This international fair of industrial technology will take place from Monday 25 to Friday April 29th. You will find Mevoco at booth B64 in hall 13.

This five days event takes place in the city of Hannover in northern Germany. Come and visit us, put your questions and discover the latest innovations that Mevoco has in store! More information can be found on the website of the Hannover Messe organization.

Mevoco again present at the Hannover Messe

/in Nieuws-HetVeer, Nieuws-Mevoco /byAs in the previous years, Mevoco will again be present at the Hannover Messe. This international fair of industrial technology will take place from Monday 25 to Friday April 29th. You will find Mevoco at booth B64 in hall 13.

This five days event takes place in the city of Hannover in northern Germany. Come and visit us, put your questions and discover the latest innovations that Mevoco has in store! More information can be found on the website of the Hannover Messe organization.

SGC strives for high precision welding

/in Nieuws-HetVeer, Nieuws-SGC /bySGC – SwitchGear Company disposes of two welding robots, each of them providing highly targeted work. Our latest automated machine acquisition clearly demonstrates our focus on precision work. Before the robot enters into action, the sheet metal work is placed accurately and stable in its final position. On that way, we avoid any risk of shifting of the plates during the welding process.

The high degree of automation of this robot is also reflected in the fact that the actual welding time per session can be seen of the screen by the means of well located sensors. With the help of light buttons, one can see very quickly in which position the welding robot is located. When the robot is welding, the doors around the machine are locked with a fence partly consisting of light coloured translucent plexiglas. An exhaust system is directly connected to this welding machine. On this way, SGC is committed to a highly precise and user-friendly production process.

SGC strives for high precision welding

/in Nieuws-HetVeer, Nieuws-SGC /bySGC – SwitchGear Company disposes of two welding robots, each of them providing highly targeted work. Our latest automated machine acquisition clearly demonstrates our focus on precision work. Before the robot enters into action, the sheet metal work is placed accurately and stable in its final position. On that way, we avoid any risk of shifting of the plates during the welding process.

The high degree of automation of this robot is also reflected in the fact that the actual welding time per session can be seen of the screen by the means of well located sensors. With the help of light buttons, one can see very quickly in which position the welding robot is located. When the robot is welding, the doors around the machine are locked with a fence partly consisting of light coloured translucent plexiglas. An exhaust system is directly connected to this welding machine. On this way, SGC is committed to a highly precise and user-friendly production process.

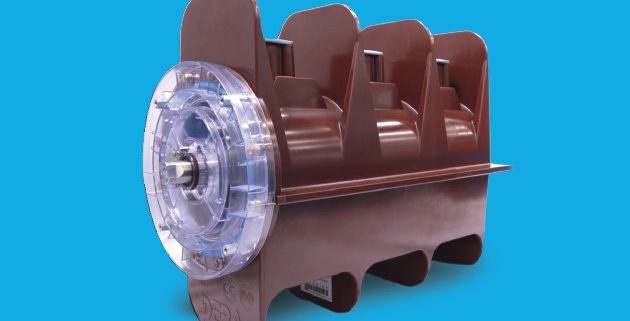

The manometer of SGC ensures user-friendly and fast fault detection

/in Nieuws-HetVeer, Nieuws-SGC /by Since we operate in a sector where safety is of exceptional importance, SGC – SwitchGear Company puts a clear focus on strong visual communication and usability in the material. These pillars are also reflected in our own developed manometer.

Since we operate in a sector where safety is of exceptional importance, SGC – SwitchGear Company puts a clear focus on strong visual communication and usability in the material. These pillars are also reflected in our own developed manometer.

The manometer of SGC is a device measuring the pressure of the SF6 gas in the cubicle. In case of a loss of pressure the device indicates that it would not be saving to operate the load break switch. Therefore, we choose at SGC to develop a manometer so friendly to use as possible and straightforward to read. This is done through colour codes printed on the manometer. If the needle of the manometer points to the green zone, it is completely safe to operate the switch. If the needle points to the red zone, it is recommended not to switch and to contact SGC. When the cubicle is fitted with an arc-killer, a third colour (yellow) is displayed on the manometer. If this zone is pointed by the needle, the arc-killer entered into force because of an internal fault and the switch should than be replaced.

Our manometer increases the user-friendliness, as – in presence of an arc-killer – there is no longer need to reach manually and directly the contacts to insure if in the case of an internal fault, it has worked or not. The measuring device provides thus a faster and more user-friendly visual error checking. Those are values that SGC is explicitly pursuing.

The manometer of SGC ensures user-friendly and fast fault detection

/in Nieuws-HetVeer, Nieuws-SGC /by Since we operate in a sector where safety is of exceptional importance, SGC – SwitchGear Company puts a clear focus on strong visual communication and usability in the material. These pillars are also reflected in our own developed manometer.

Since we operate in a sector where safety is of exceptional importance, SGC – SwitchGear Company puts a clear focus on strong visual communication and usability in the material. These pillars are also reflected in our own developed manometer.

The manometer of SGC is a device measuring the pressure of the SF6 gas in the cubicle. In case of a loss of pressure the device indicates that it would not be saving to operate the load break switch. Therefore, we choose at SGC to develop a manometer so friendly to use as possible and straightforward to read. This is done through colour codes printed on the manometer. If the needle of the manometer points to the green zone, it is completely safe to operate the switch. If the needle points to the red zone, it is recommended not to switch and to contact SGC. When the cubicle is fitted with an arc-killer, a third colour (yellow) is displayed on the manometer. If this zone is pointed by the needle, the arc-killer entered into force because of an internal fault and the switch should than be replaced.

Our manometer increases the user-friendliness, as – in presence of an arc-killer – there is no longer need to reach manually and directly the contacts to insure if in the case of an internal fault, it has worked or not. The measuring device provides thus a faster and more user-friendly visual error checking. Those are values that SGC is explicitly pursuing.

Headquarters Landegem

Moorstraat 24, 9850 Landegem (Belgium)

T.: +32 (0)9/371.75.51

General: info@deba.biz

Sales/Tenders: sales@deba.biz

BE 421.426.594

Deba on Channel Z: over 40 years of medium voltage

Namur regional office

Chemin du Bois aux Mouches 8,

5590 Ciney (Belgium)

T.: +32 (0)83/68.90.87

namure@deba.biz

New vacancies

Limburg Regional Office

Westlaan 268,

3550 Heusden-Zolder (Belgium)

T.: +32 (0)13/55.46.34

limburg@deba.biz